Tag: Automatic Plastic Material Hopper Dryer | Injection Molding Auxiliaries | Industrial Plastic Hopper Dryer | Plastic Drying Machine

Tag: Plastic Material Auto Loader | Plastic Raw Material Loading Machine | Plastic Vacuum Auto Loader | Plastic Hopper Auto Loader

Tag: Water Cooled Chiller System | Water Chilling Unit | CE Water Cooled Chiller | Water Cooled Screw Chiller

Tag: Plastic Shredder | Manual Plastic Crusher | Plastic Crushing Machinery | Plastic Crusher Machine

Tag: Horizontal Color Plastic Mixer | Color Mixing Machine | Plastic Color Mixer Machine | Automatic Vertical Plastic Color Mixer

Tag: Plastic Dehumidifier Machine | Dehumidifying Dryer | Digital Plastic Dehumidifier | Plastic Dehumidifying Dryer

Tag: Plastic Injection Mold Temperature Controller | Injection Mold Temperature Controller | Hot Runner Mould System | Hot Runner Mold Temperature Controller

Tag: Belt Conveyor For Material Handling | Automatic Belt Conveyor | Belting Conveying Machine | Horizontal Belt Conveyor

Tag: Color Dose Mixer For Injection Machine | Masterbatch Dosing Mixer | Rotary Color Dose Mixer | Plastic Injection Color Dose Mixer

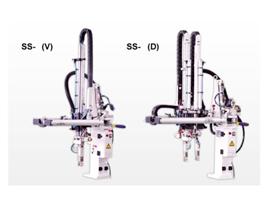

Tag: Swing Type Injection Robot Arm | Plastic Injection Auxiliary Equipment | Automatic Swing-Arm Robot | Six Axis Swing-Arm Robot